HMI Design System

HMI Design System

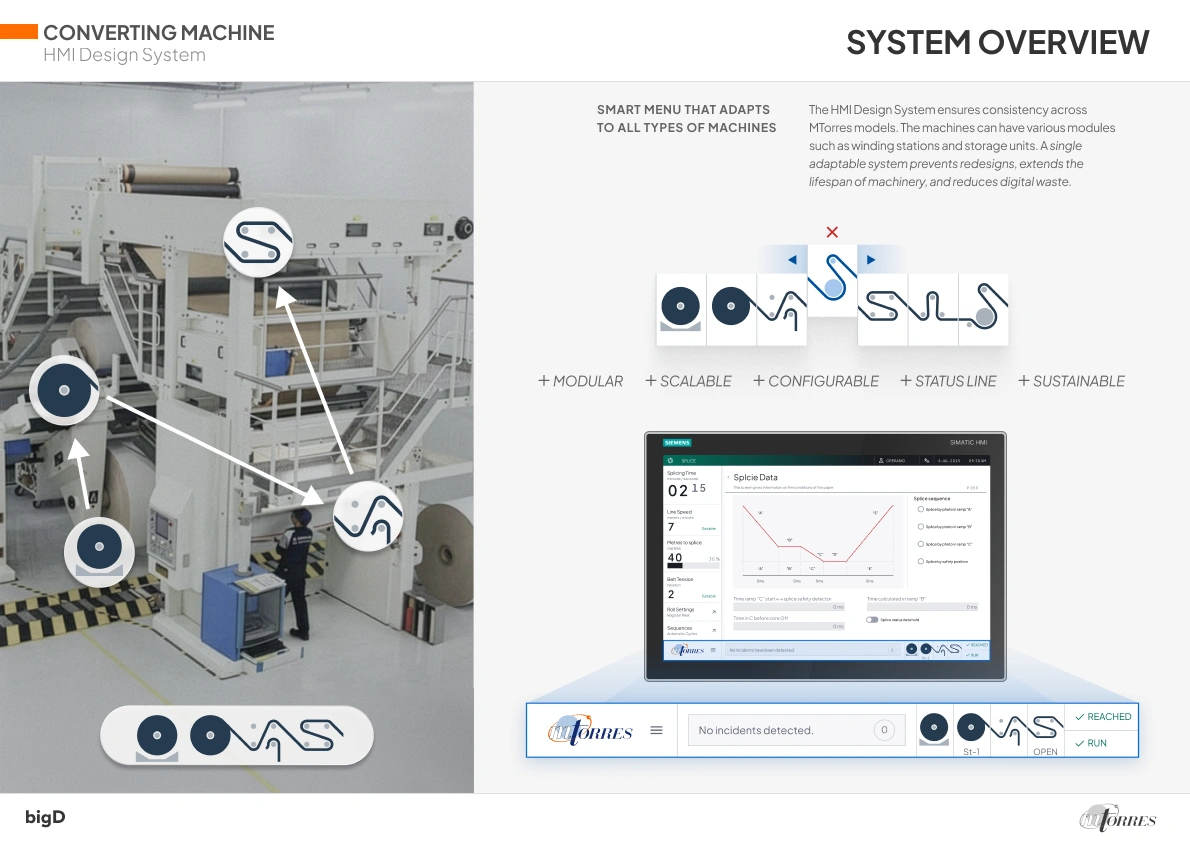

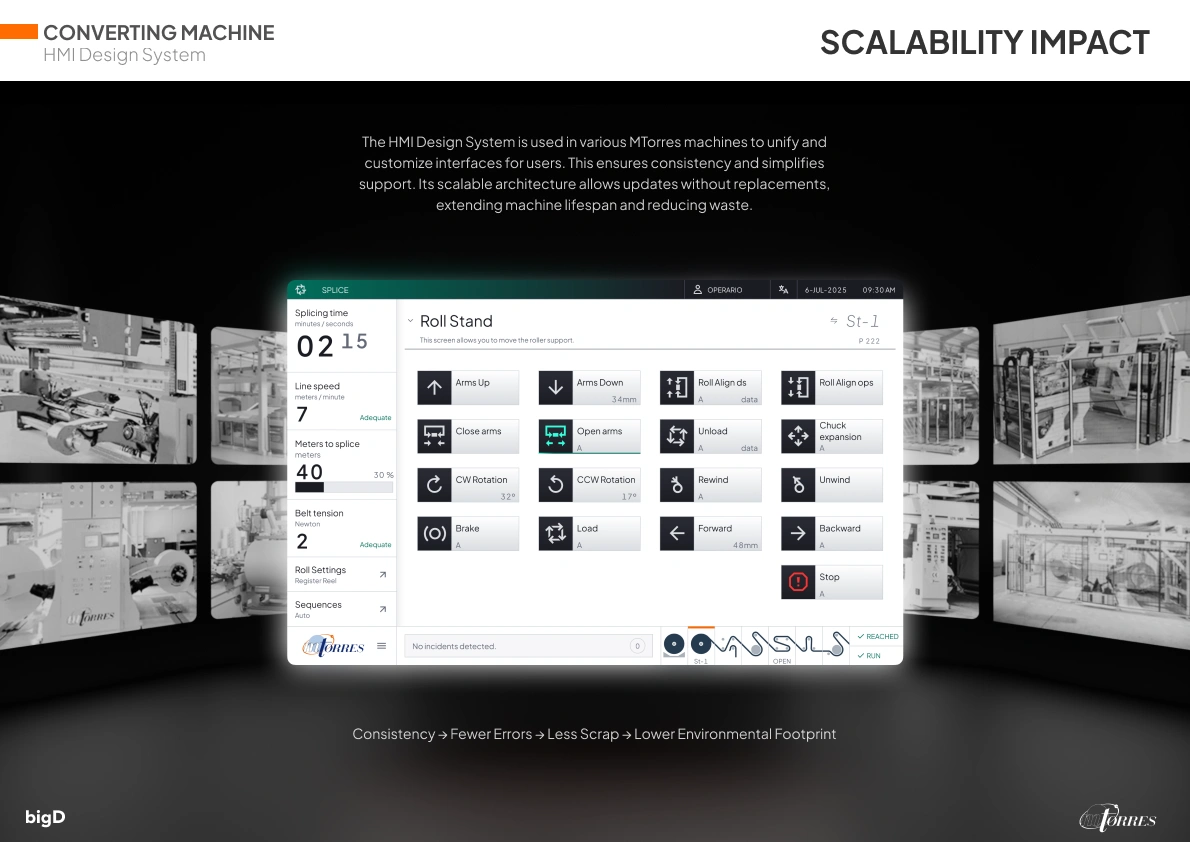

MTorres entrusted bigD with the development of a unified HMI design system for its converting machines. The goal was to create a scalable and consistent interface that could be adapted to different machine configurations, improving the operator experience, reducing errors, and extending the digital life cycle of the equipment.

The result is a modular, configurable, and sustainable HMI Design System that can be applied to different models and is ready to evolve without the need for constant redesigns.

Experience Analysis and Improvement

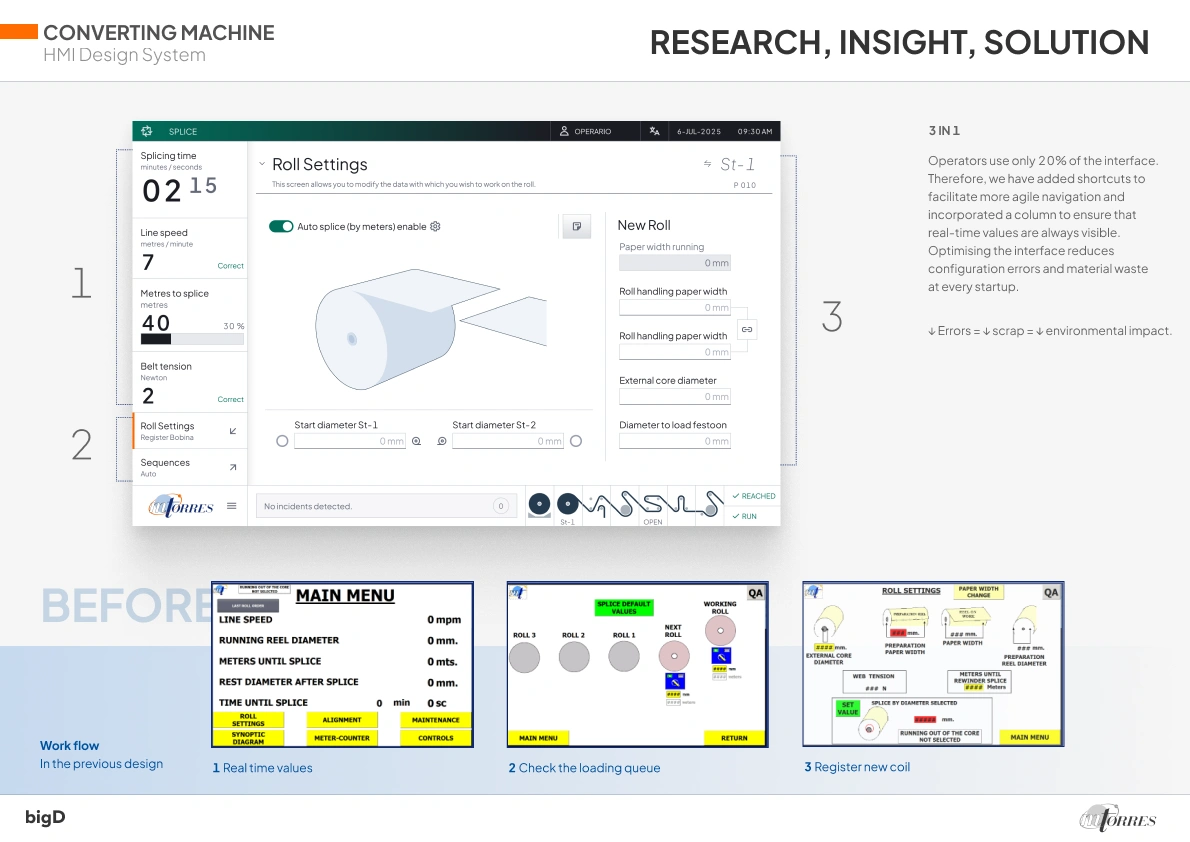

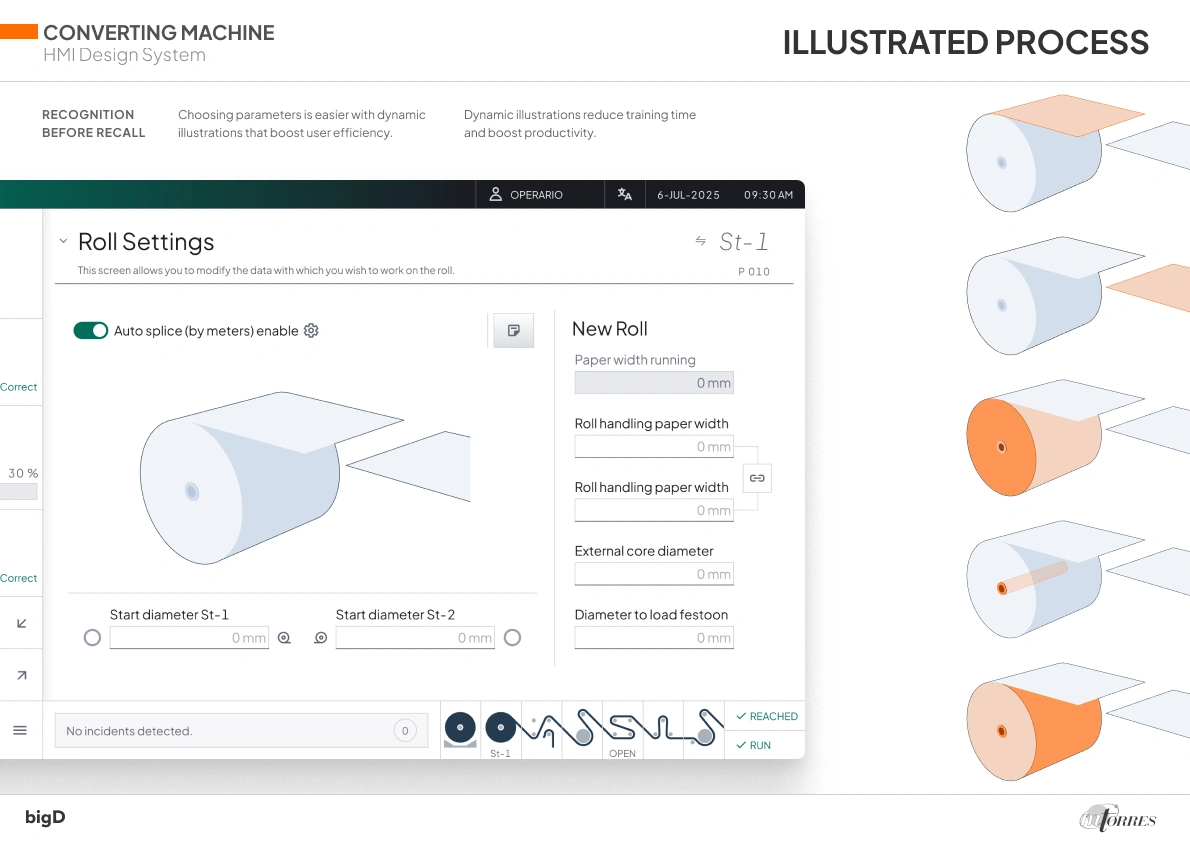

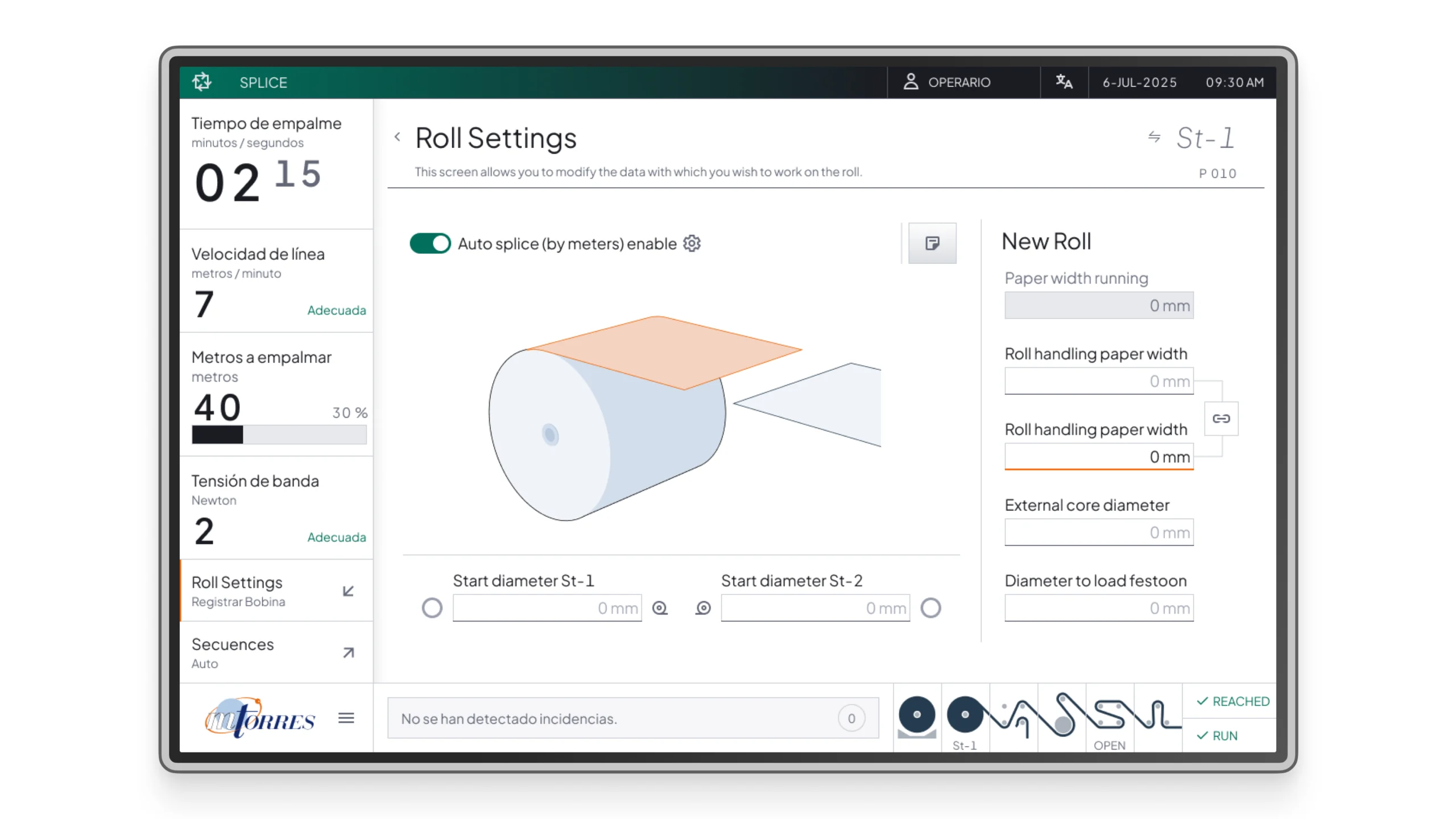

The project began with an in-depth analysis of how operators actually use the machine, revealing that interaction is concentrated on a small number of functions. Based on this, the design prioritizes critical information, simplifies flows, and provides shortcuts to the most frequently used actions.

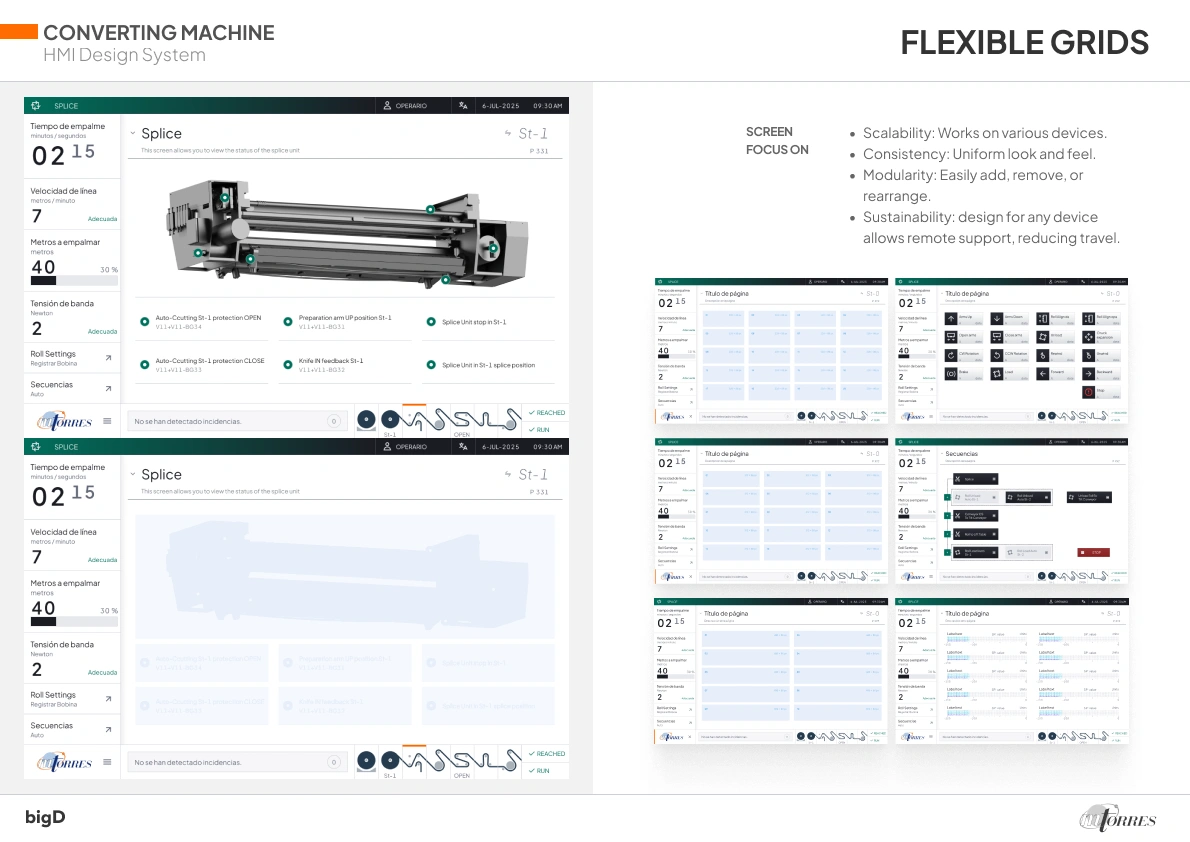

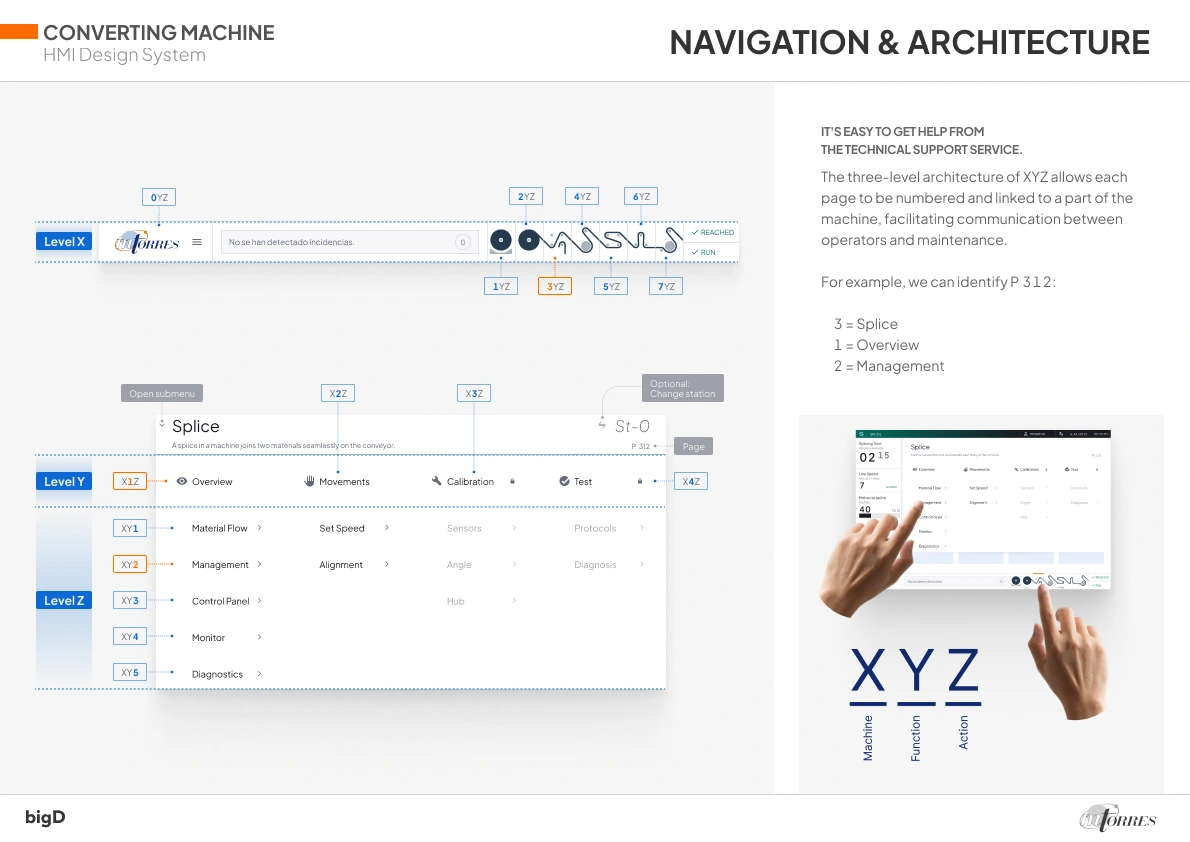

The interface is organized using a modular and hierarchical architecture, with a central area for main interaction, side columns for machine status and secondary actions, and structured navigation that connects each screen to a specific part of the equipment. This approach reduces configuration errors, minimizes material waste at each start-up, and speeds up the learning curve for the system.

Design System, Scalability, and Impact

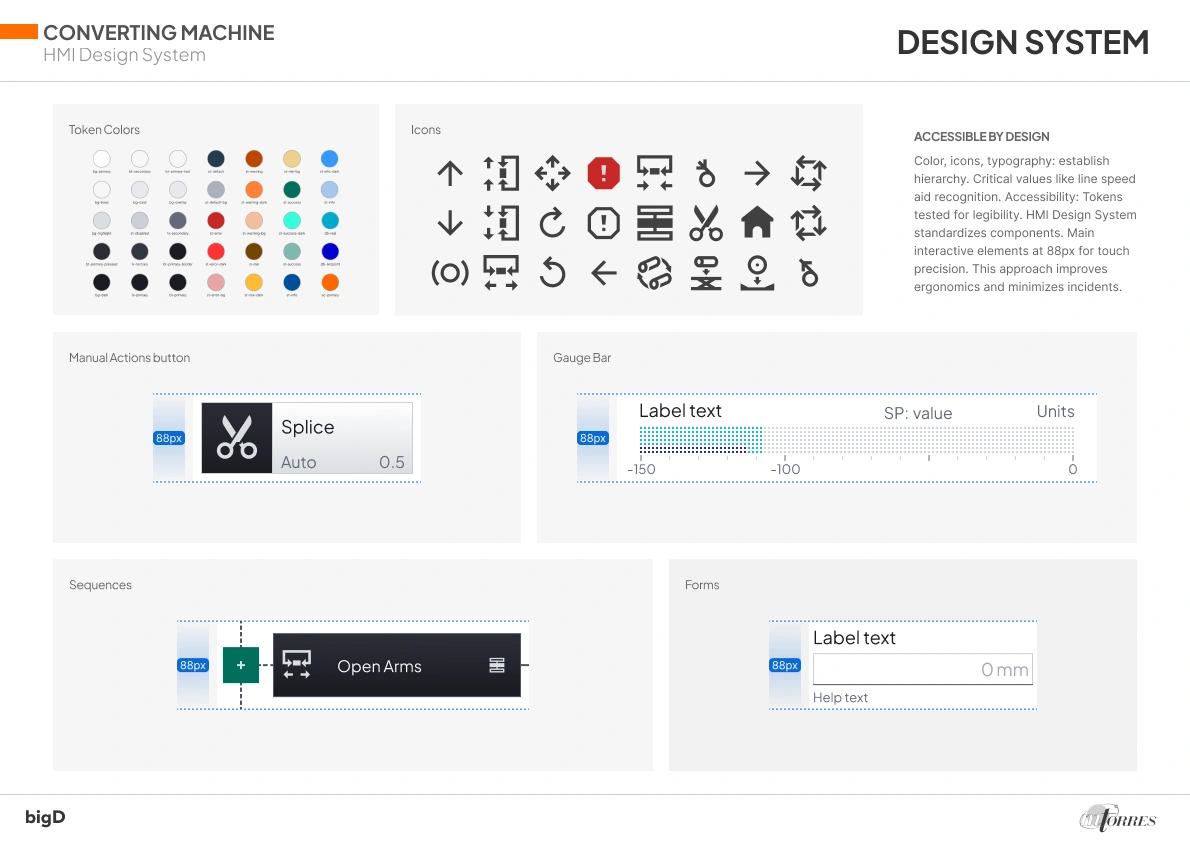

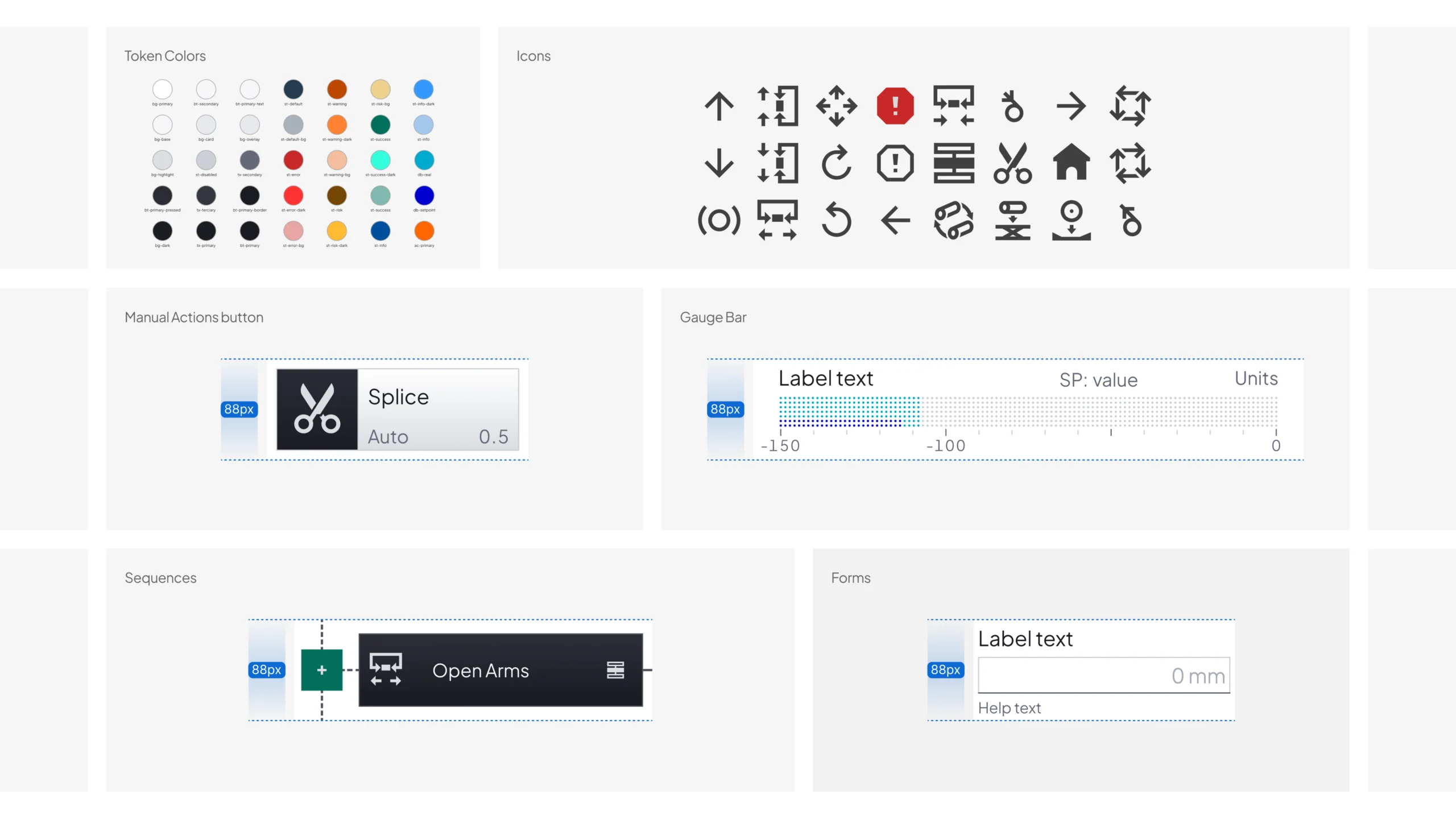

A specific design system was developed for industrial environments, defining components, iconography, typography, and interaction criteria optimized for touch screens, based on principles of ergonomics, accessibility, and precision.

The result is a scalable and sustainable HMI Design System that allows interfaces to be customized without losing consistency, facilitates updates without replacing hardware, and reduces the environmental impact associated with digital redesigns. Visual and functional consistency translates into fewer errors, less scrap, and a longer machine life.