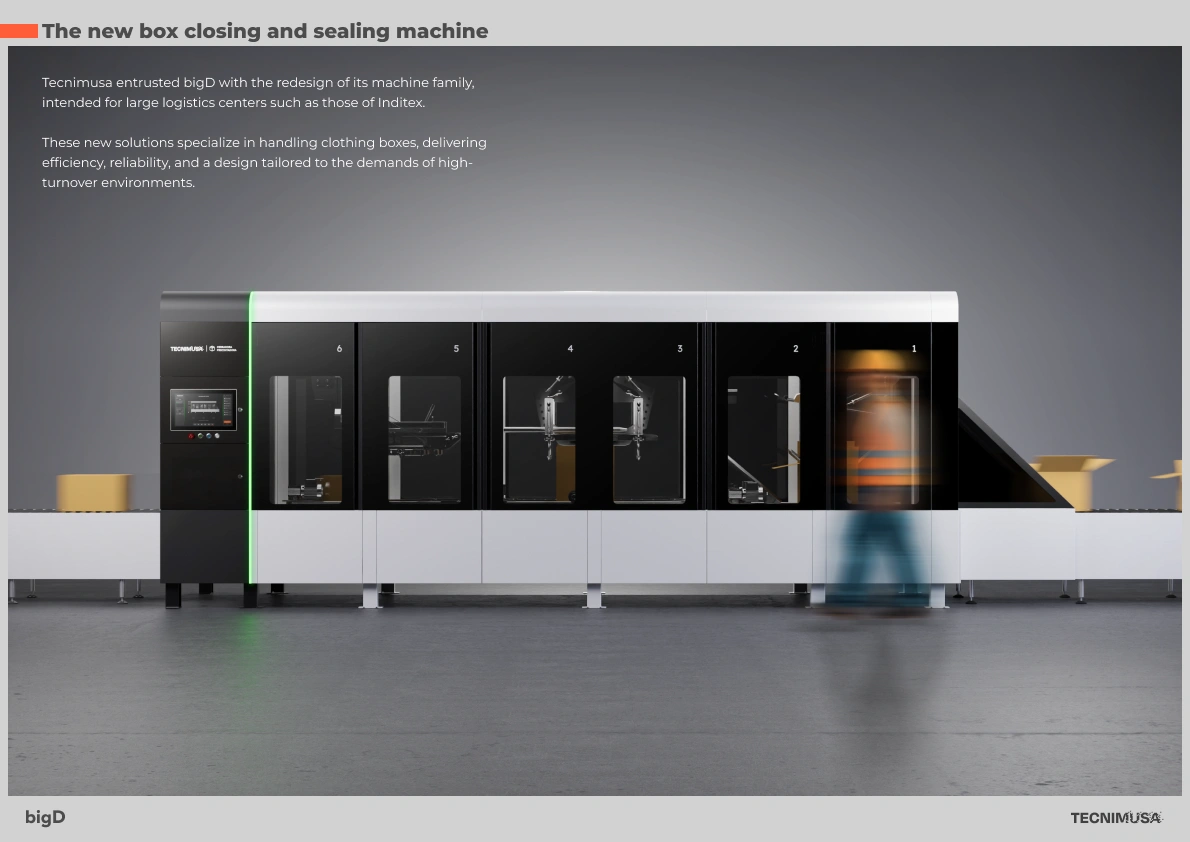

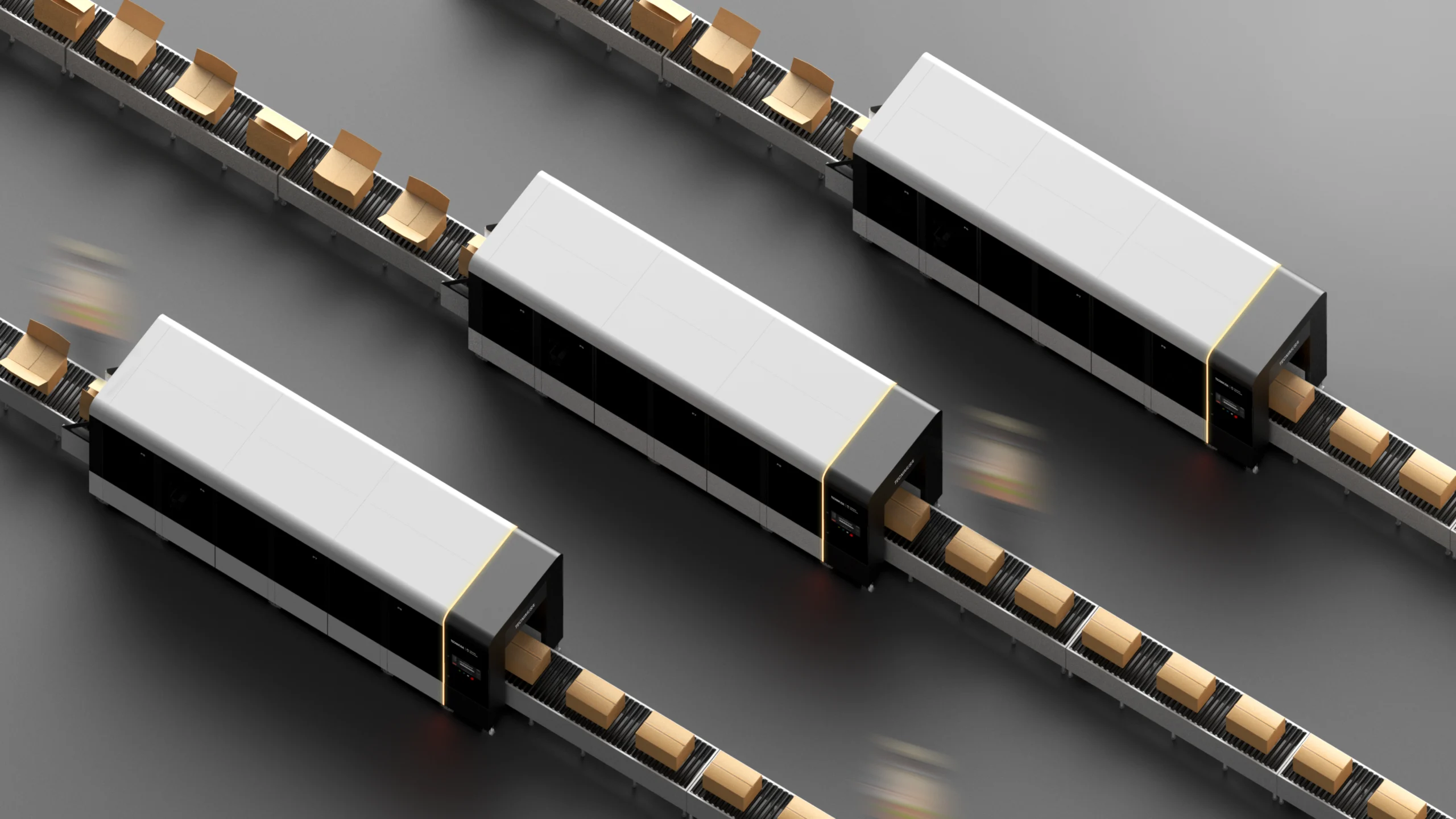

Box Closing and Sealing machine

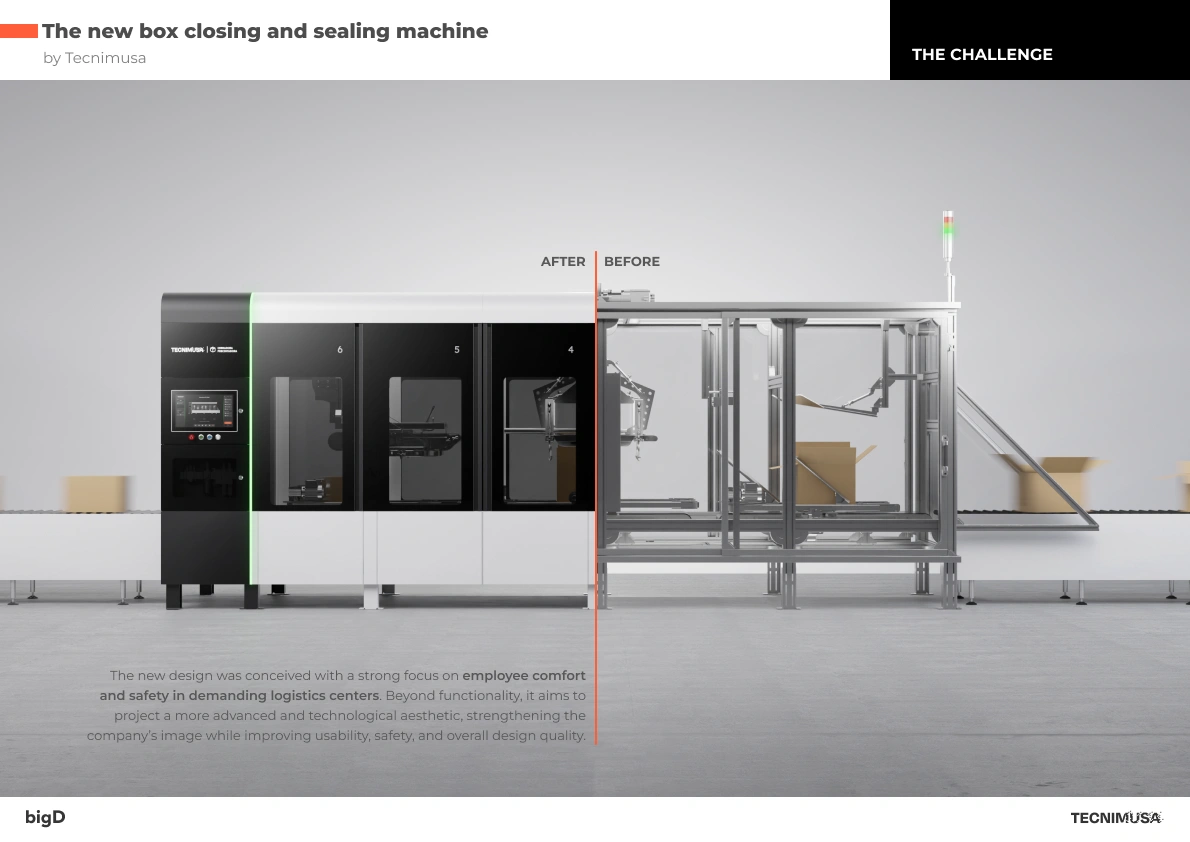

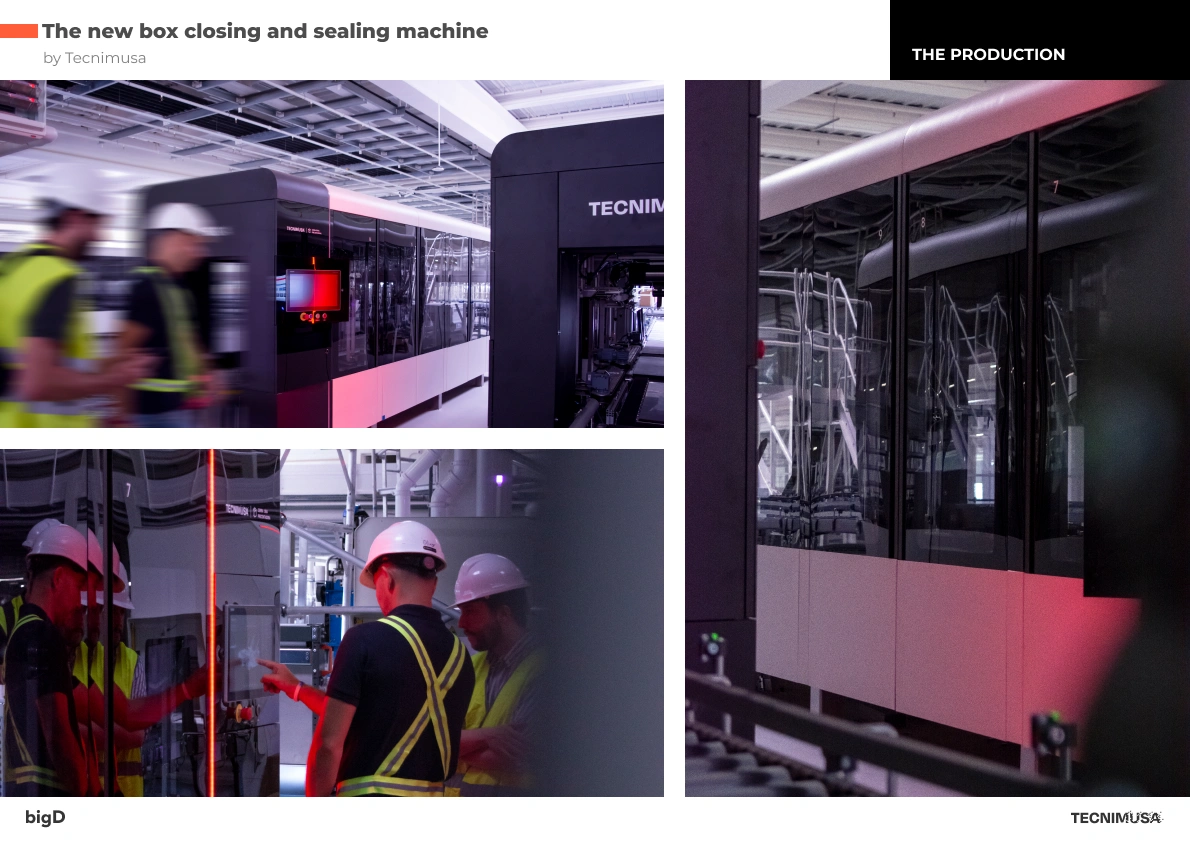

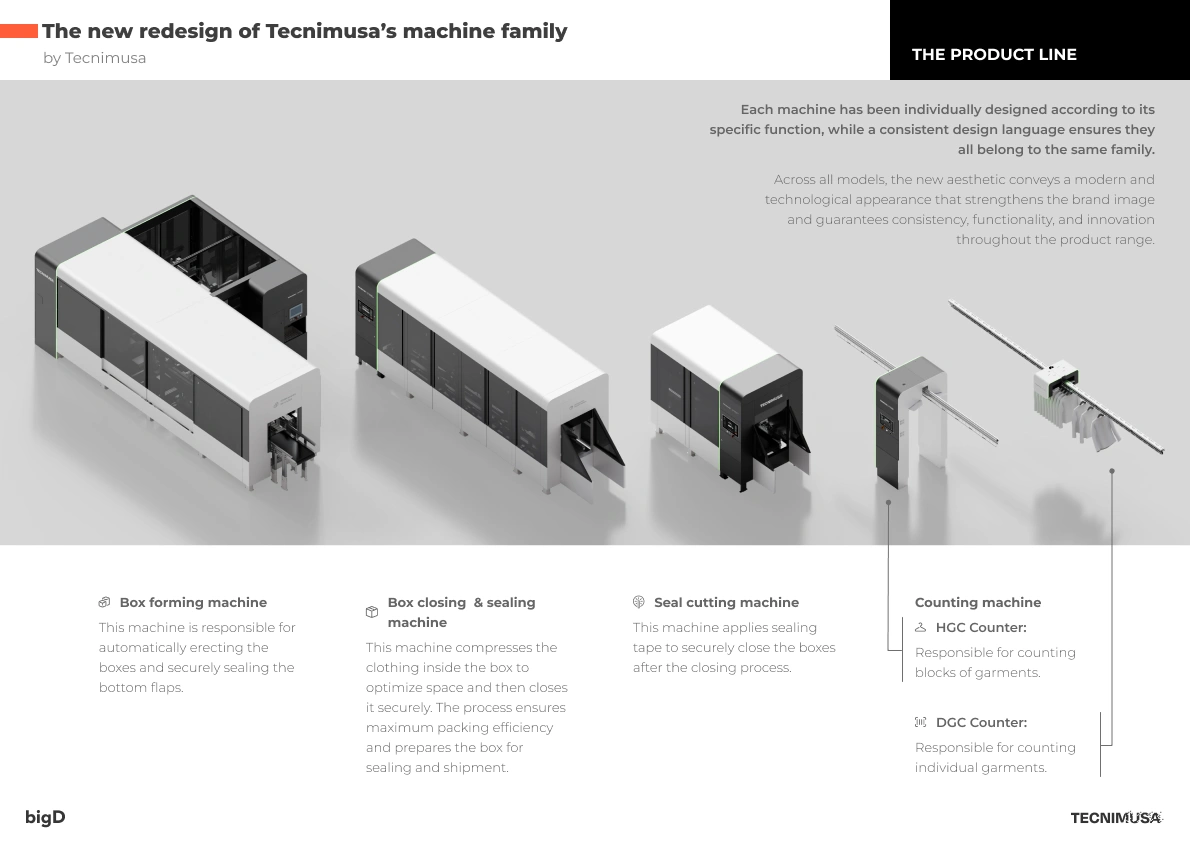

Tecnimusa commissions bigD with the Industrial Design of its new box closing and sealing machine. Our mission in this project has been clear: to rethink the entire machine to adapt it to the quality, efficiency and design standards required in a large-scale operating environment. From its modular architecture to the digital interface (HMI), we have worked on every detail to ensure a seamless integration between the physical and the digital, achieving a last generation “Phygital” solution.

Design

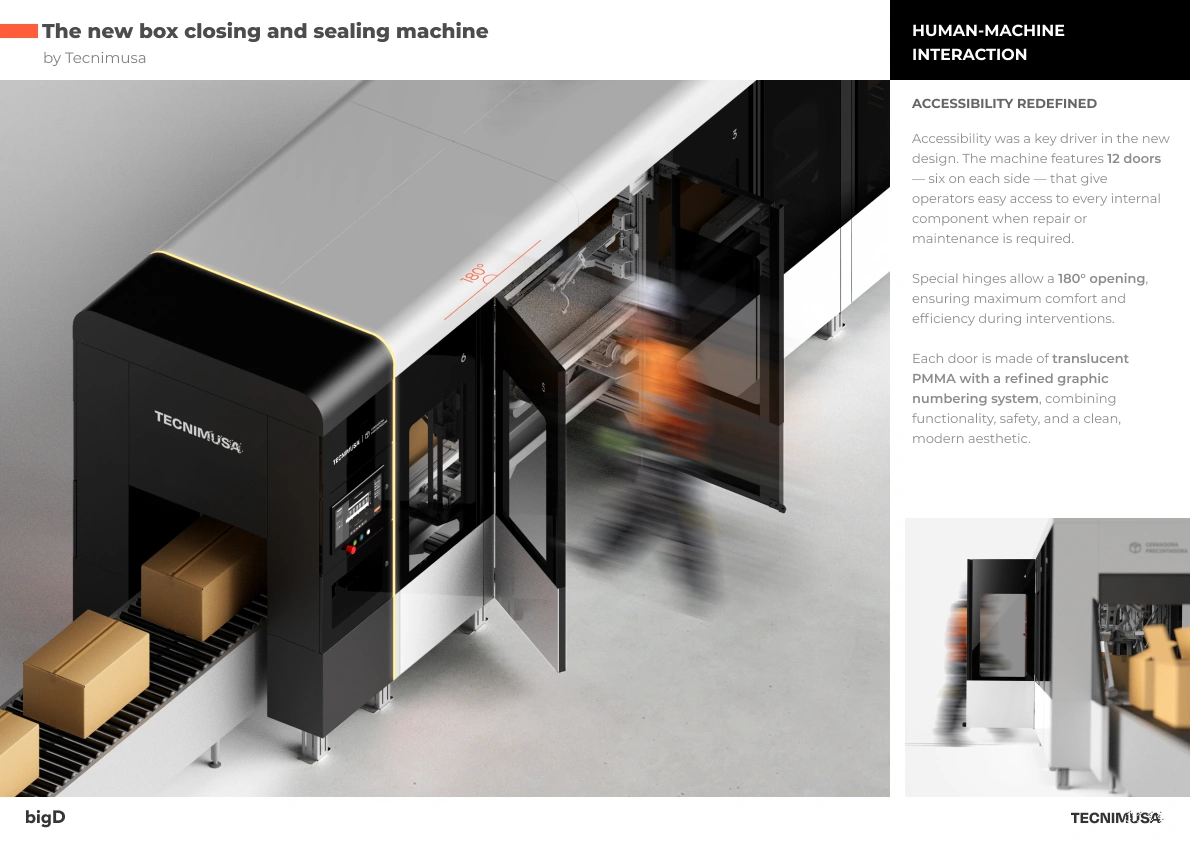

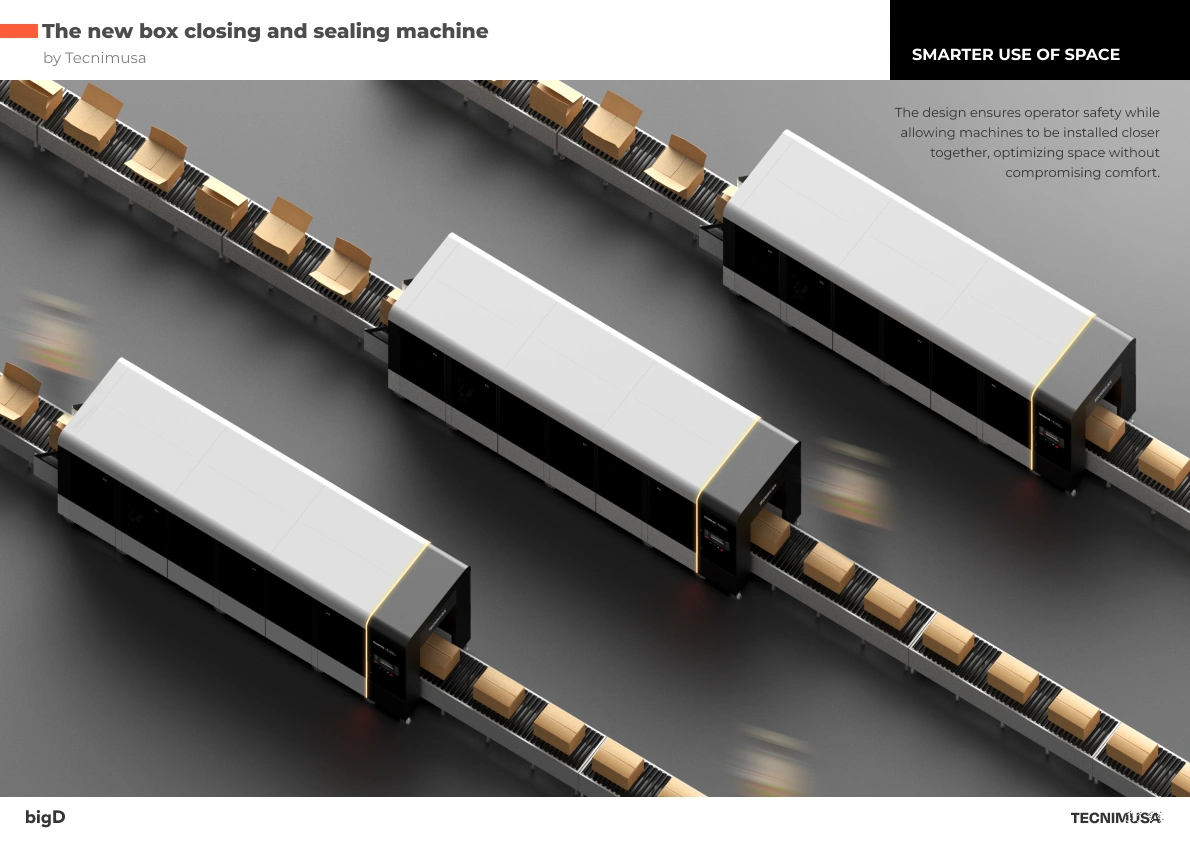

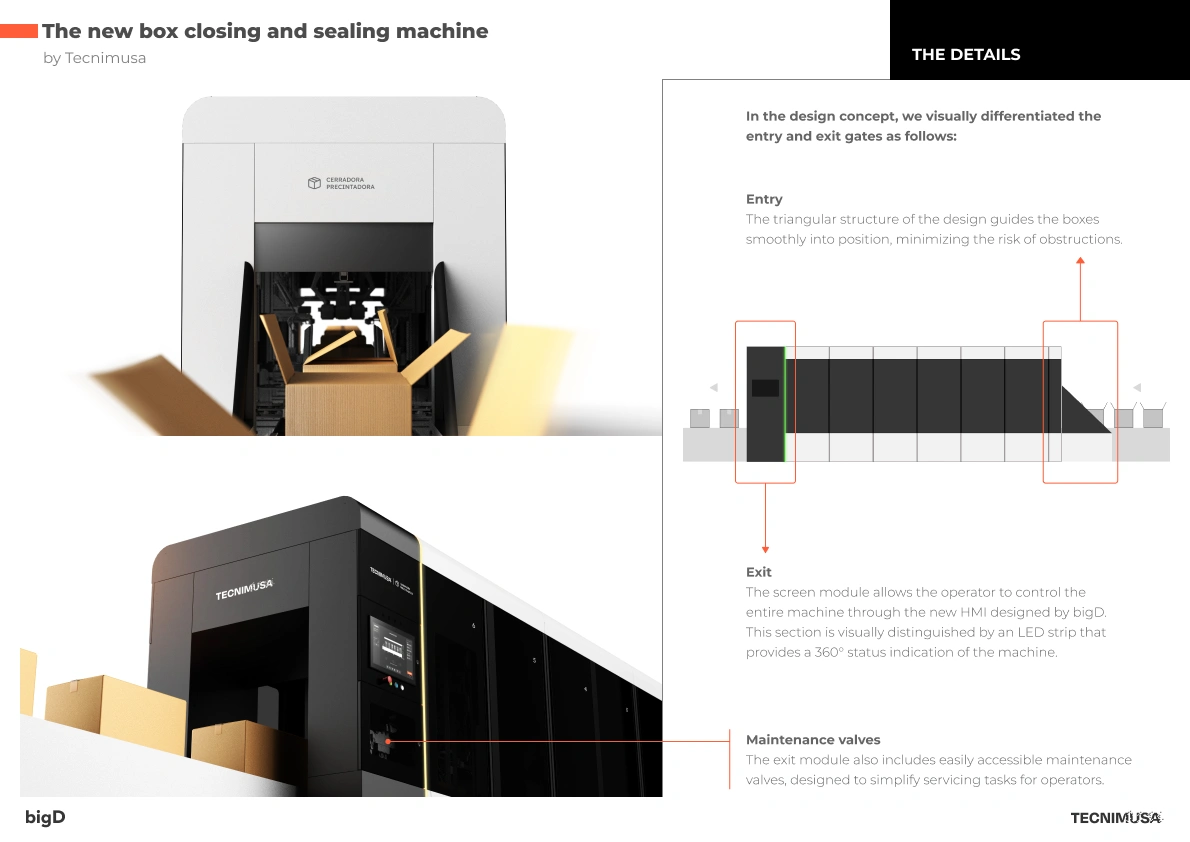

We created a design that balances modern aesthetics and advanced functionality for high-demand logistics environments. The modular architecture optimizes installation and maintenance, adapting to changing needs. Its appearance conveys innovation and professionalism, differentiating it in the market. In addition, we redesigned the HMI interface, improving ergonomics, navigation and interaction to maximize operator productivity.

Development

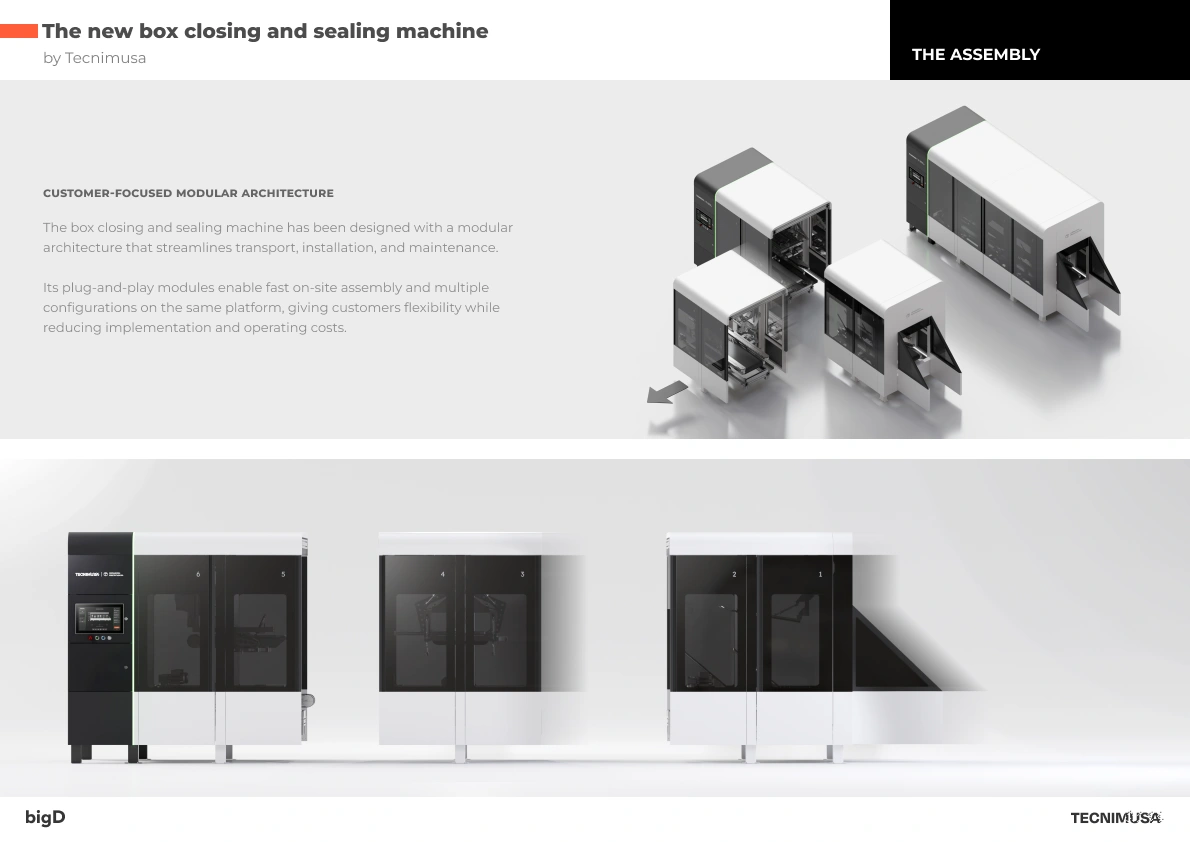

We have optimized the design to integrate it with the customer’s systems and mass production. Each component meets functional and regulatory standards, ensuring protection and ergonomics. Modularity allows for efficient assembly and independent operation if required. In addition, we perform simulations, 3D prototypes and physical tests to ensure optimal performance prior to manufacturing.

Manufacturing and Assembly

We have manufactured all parts in metal sheet, ensuring robustness, precision and a high quality finish. Subsequently, we carry out the complete assembly in our facilities to guarantee its correct integration and functionality. Finally, we send the assembled systems to the customer for their incorporation in the machine and their implementation in the logistics centers.