Human Machine Interface (HMI) is one of the most prominent aspects of industrial automation because it is a user interface or control panel that connects a person to a machine or device. Although the term can technically be applied to any display for performing control functions and receiving feedback on those actions, HMI is used in the context of industrial processes that control and monitor production machines.

Human-machine interface systems enable technology operations in every application, including machining centres, semiconductor production equipment and medical diagnostic equipment, for example.

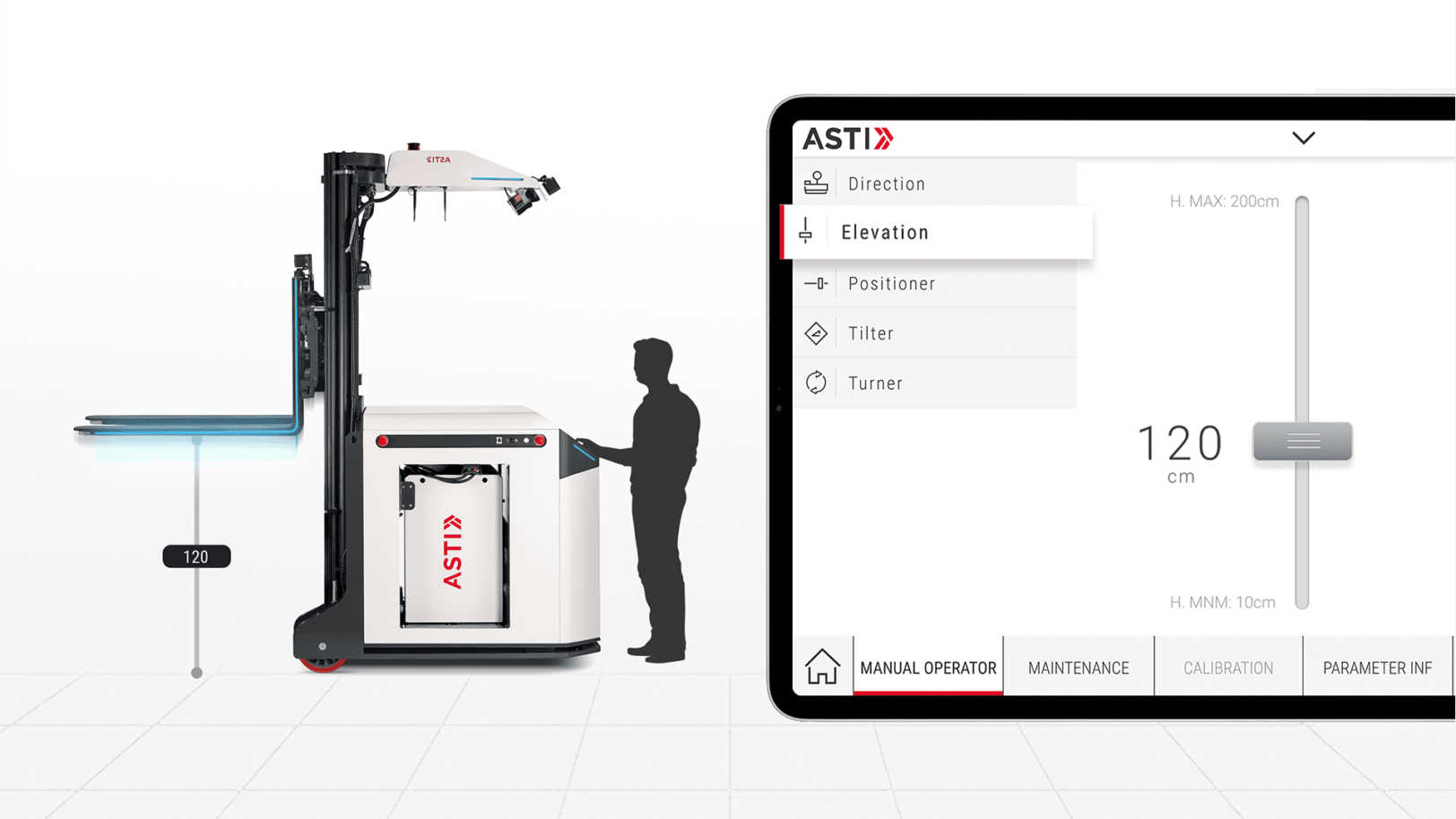

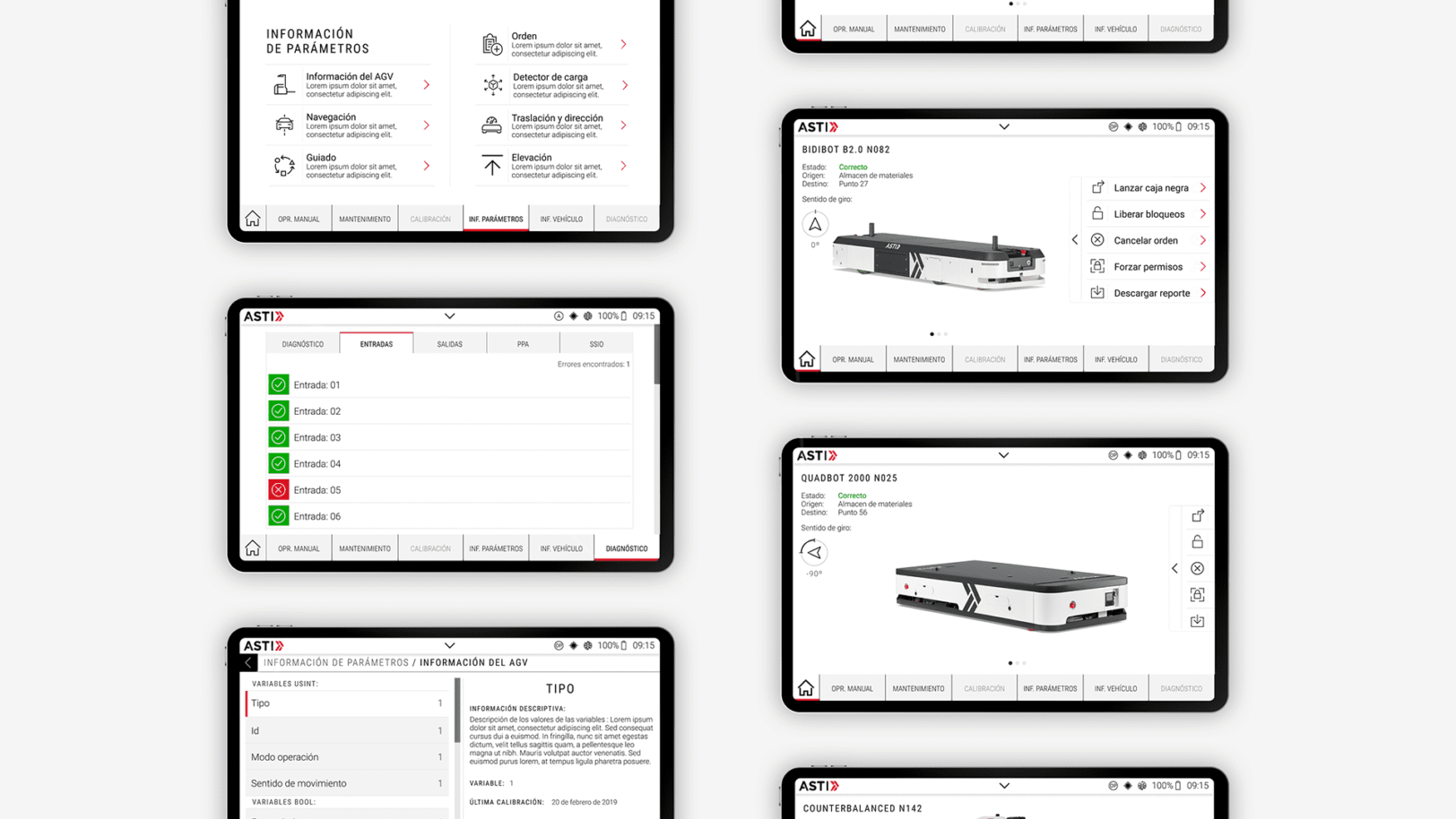

In short, the HMI interface encompasses all the elements that a person will use. For example, if a maintenance operator controls or monitors machinery from the HMI, it can include information such as temperature, pressure, exact positions of production lines or the control of raw material tank levels, among many other functions.

In addition, these control panels can be connected to PLCs and display their problem-solving behaviour to the maintenance technicians to improve times.

Thanks to this technology, automation is incorporated and many problems caused by lack of information or human error are reduced. In addition, the basic functions to be highlighted are: Data visualisation, production time tracking, monitoring of KPIs and machine inputs and outputs.

As data takes on an increasingly essential role in manufacturing, the future looks bright for HMI operator panels. The technology may have come a long way, but its growth potential remains virtually limitless.

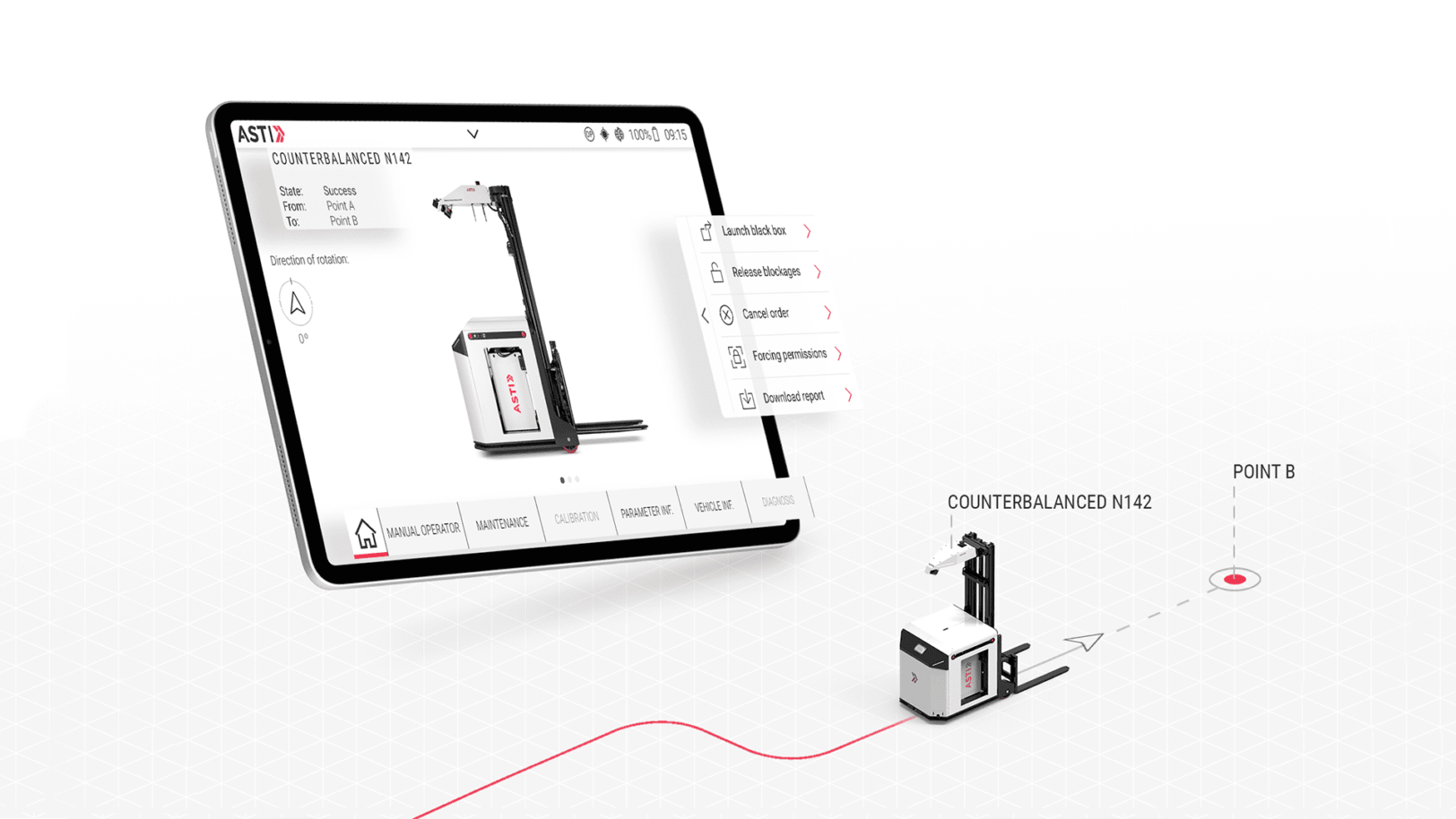

An important point for good adoption is to get a design for HMI displays that is simple, effective and functional for operators. If it has a good interface, the degree of acceptance will be very high. Using light-coloured or gradient backgrounds is less tiring for the eyes and this is an important point to take into account. We should not think about how our smartphone works in order to apply it here because neither the purpose is the same nor the functionality.

The screens have to be clear and allow quick interactions to access any part, taking into account that an organisation has to be the basic pillar within the HMI and the menus have to be clear.

What must be clear is that the HMI does not collect or record information, nor does it connect to databases. The interface provides a communication tool that works in conjunction with a SCADA system.

Discover more about bigD’s groundbreaking project, the HMI Interface for ASTI, on our webpage: https://bigd.es/casos/asti-interfaz-hmi/.