The International Federation of Robotics (IFR) indicates that we have reached 3 million operational robots in factories around the world. This represents an increse of 10% in 2021 compared to 2020, a fact that should not be overlooked.

More and more companies are daring to automate, seeing the great advantages that robotics brings to their businesses. It is true that we come from an unusual stage but, even so, the trend of transforming through robots continues.

In the context of Industry 4.0, the use of robots will help us to increase operational capacity and speed up times by triggering this great change and impact on the industrial sector. But, how do I know which robots are best suited to my business?

There are many doubts that may arise when choosing between the different types of robots, but with these inputs and questions that we leave, you can have a much clearer view of what is needed. We even advance you that they are complementary in some occasions.

So, don’t close yourself to a single choice for everything! Above all, think long term! This will help you to have an agile and lasting planning in time.

As Stella Terrill Mann says, “Every time we say “be!” in any form, something happens”. And in robotics, it is happening.

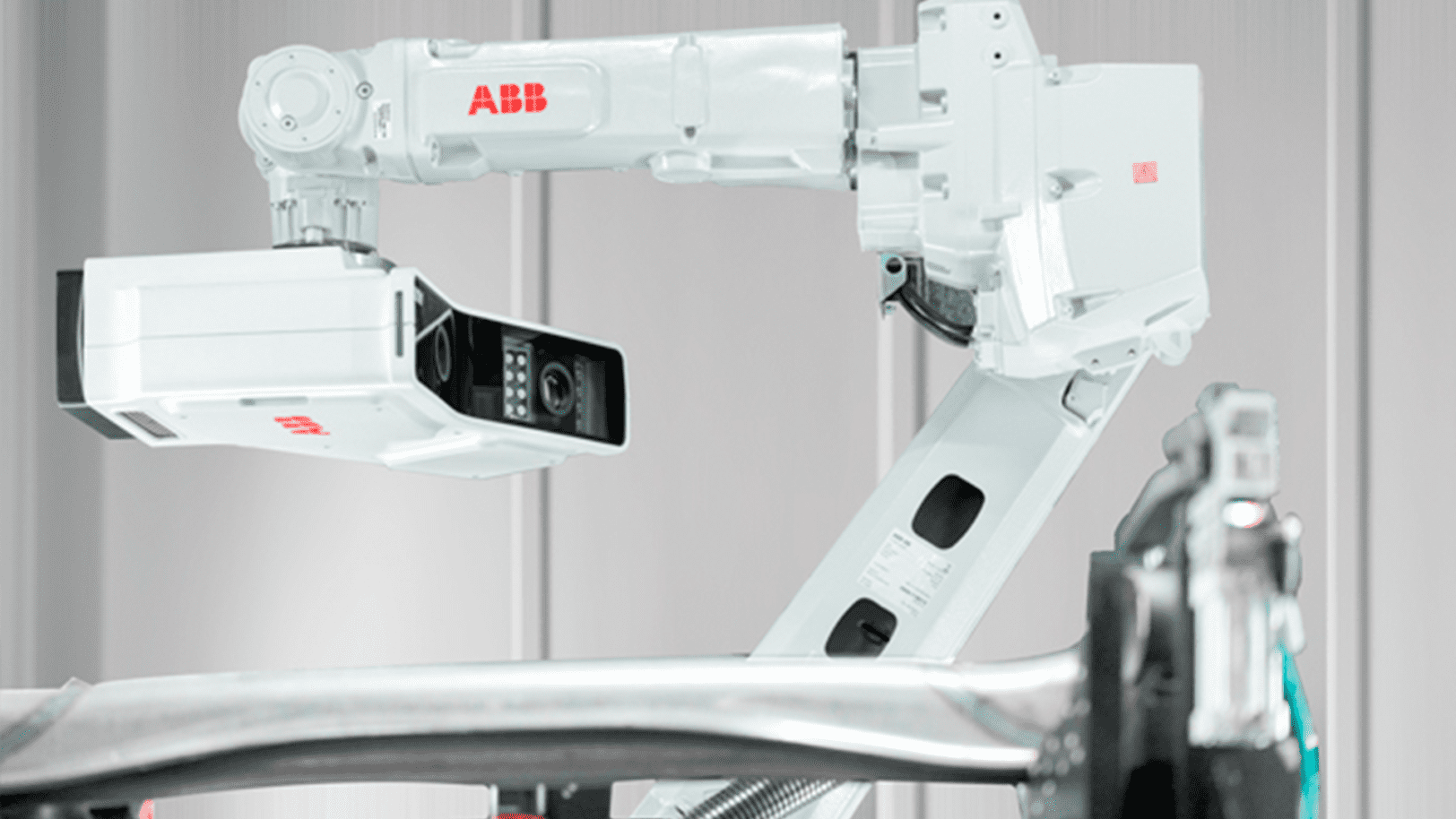

Project ABB – 3D sensor

According to the UNE-EN ISO 8373:2012 Standard: “Industrial robot is a multifunctional manipulator, automatically controlled, reprogrammable in three or more axes, which may be stationary or mobile for use in industrial automation applications”.

On this basis, we can say that the industrial robot produces in large volume, takes up a lot of space and is usually fixed in one place. While the cobot is compact, occupies little space and can be easily relocated. But the first ones will need great security measures and the second ones are designed to work with people.

Against this background and based on the IFR report, which has served as a preamble, we will discuss the 4 main trends in robots:

- New industries join the revolution: Some sectors of the manufacturing industry, relatively new to automation, have opted to integrate robots into their operations. The rise of e-commerce has revolutionized everything from internal logistics to returns and labor shortages. Logistics is one of those sectors in which digitalization, through the implementation of robots, has left no one indifferent.

- Ease of use: Installing and using a robot has never been so easy. The user interfaces allow simple and easy programming and customization.The software/hardware combination is a tandem that has reduced its complexity for the benefit of users. If we add to this a trend towards low-cost robotics, because they already come pre-configured and come with grippers, sensors and controllers, the combination is perfect.

- The data generated supports digital automation: We must mention the special importance of data collection and the use of data in production processes. If we have data, we have a great advantage in operations. The information obtained in automated processes will lead to make much more accuate decisions.

- Robot and human cooperation: With more and better education on automation and robotization, the momentum for its adoption and widespread use has increased. Manufacturers such as ABB and ASTI are continually training their equipment and updating their designs to meet current needs and those of their customers.

Learning the principles of robotics and automation has opened the opportunity to be much more efficient and have a greater mastery of the situation by the work teams.

Now that we know their main differences and are aware of the latest trends, are you ready to enter the world of robotization? If so, here are a few questions you can’t help but ask yourself.

– Are we going to have to control the robot in person?

– What movements will it make? How far will it travel?

– Are repetition, precision or both essential?

– Does vision need to be integrated into the robot?

We know these are not easy to answer, but they will help you understand what you need. Keeping in mind the big differences and the market trend, it’s all about getting started.

As Henry Ford said: “Don’t find the fault, find the remedy”.

From bigD we support companies in the design of their new self-guided vehicles among other types of robots. From conceptual design to engineering of plastic parts and contact with suppliers, let’s talk?