Due to the current needs of companies, technological development has accelerated to such an extent that the Industry 4.0 or 5.0 debate has already arisen. But what we are really seeing is the interconnection of digital sensors for the analysis and management of machine-generated data as well as the use of SCADA and HMI systems.

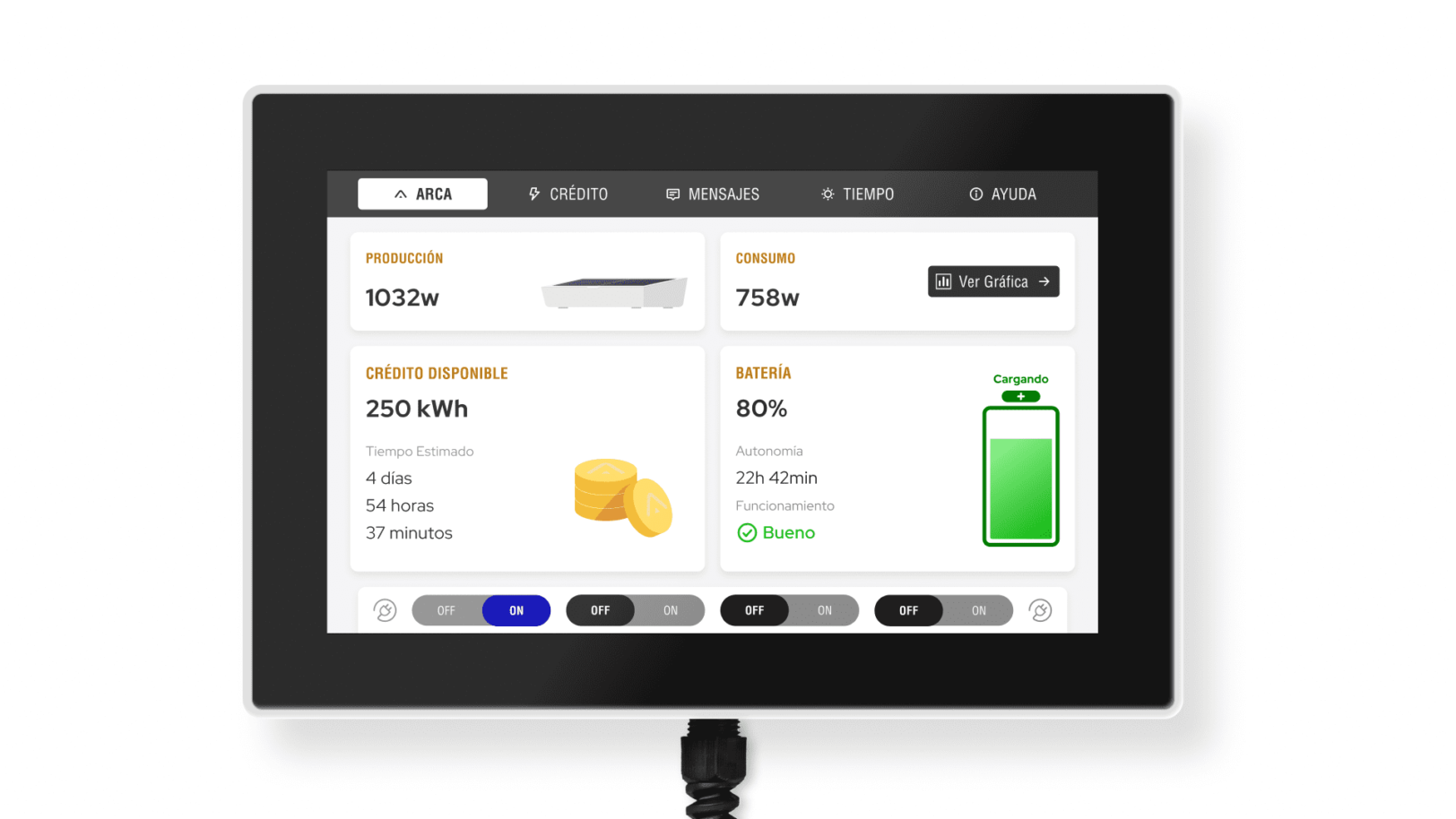

When designing a human-machine interface system, we must always think about a functional and simple design that incorporates enough information for machine operators to be able to use it correctly without any margin for error.

Simplicity and attractiveness should not be at odds, an HMI design is the image and value proposition of the brand as well. That is why machine manufacturers are paying more and more attention to their design. Design, an ambiguous term, but with the clear objective of transmitting and providing a solution. The end result of any kind of design is only the tip of an iceberg. What we do not see is difficult and intensive work in terms of development, but in the long run it will be a great advantage for the organisation and its operators.

The elements of functional design is the process of responding to the needs or desires of the people who will use this system in a way that meets their needs in a simple and understandable way. Functional design is both an outcome and a process.

In order to achieve a simple, effective and functional design for HMI machine screens for operators, the following must be taken into account.

The screens that are installed in the applications must have, in some cases, customised designs adapted to the needs of the operator. In addition, it is possible to install HMI screens with Internet connection, allowing it to send messages in the event of anomalies or for our technical service to connect remotely to carry out the corresponding services in each specific case.

It is important to have clear sections and ideas. If we are going to divide the screen navigation, it must be supported by a diagram that allows us to see the flows between screens. In the case of personalisation, dividing the screens into the following sections could be of great help.

– Work focus: 95% of time will be spent on this screen, with access to data entry and basic visualisations.

– Editing pillar: configuring machine or system parameters is important, but should be reserved to a few profiles. In other words, restricting their access should be considered for better functionality.

– Alarms: having access to a history of alarms and visualisation of the current alarms we have, as well as information on how to resolve incidents is key.

– Production and maintenance. Designed for machine production data complemented with a much more complex analysis by shifts and data. In addition to incorporating manuals and data on machine maintenance.

Being able to integrate different types of documentation such as manuals or machine diagrams on the screen is very useful and effective, even incorporating videos. Designing the HMI should be personal if we can choose, but the most important thing is that the design should be simple, clear and functional.

Discover more about bigD’s groundbreaking project, the HMI Interface for IED Electronics, on our webpage: https://bigd.es/en/mas-proyectos/arca/